A twin shaft shredder or msw twin shaft shredder in India is a powerful machine designed to efficiently shred and reduce the size of various materials such as plastic, wood, rubber, and metal. Some benefits of using a twin shaft shredder include:

High Capacity: Our Twin shaft shredders or MSW Twin Shaft Shredder in India are capable of processing large volumes of materials quickly and efficiently, making them ideal for use in industrial and commercial settings. We provide the best Industrial Plastic Shredder in India or Scrap Shredder Machine in India and also used for Food Waste to Fertilizer Machine in India.

Versatility: MSW Twin shaft shredders or Twin shaft shredders can handle a wide range of materials, including hard and soft plastics, rubber, wood, paper, and more. This makes them an excellent choice for businesses that need to process multiple materials.

Reduced Maintenance: The design of twin shaft shredders is simple, with fewer moving parts and lower energy requirements, which translates into reduced maintenance and repair costs.

Improved Safety: Twin shaft shredders or MSW Twin Shaft Shredder in India have safety features that prevent accidents and injuries. They are equipped with safety switches that shut off the machine if the hopper or cover is opened.

Environmentally Friendly: By reducing the size of materials, MSW Twin Shaft Shredder or Twin Shaft Shredders make it easier to recycle and dispose of waste properly. This helps to reduce the impact of waste on the environment.

Cost-effective: MSW Twin Shaft Shredder or Twin shaft shredders are cost-effective, with low operational costs and a high return on investment. They are an excellent investment for businesses looking to streamline their waste management processes.

Wet waste composting machine In India

Overall, a twin shaft shredder in India is an efficient and effective tool that can help businesses reduce waste, improve productivity, and save money in the long run.

Some common applications of MSW Twin Shaft Shredder or Twin Shaft Shredders include:

Recycling: MSW Twin Shaft Shredder or Twin Shaft shredders in India are commonly used in recycling facilities to shred and process a variety of materials such as plastic, paper, metal, and wood. This helps to reduce waste and make recycling more efficient.

Industrial Waste: Twin shaft shredders or industrial plastic shredder in India / scrap shredder machine in India can also be used to process industrial waste, such as plastic packaging, cardboard, and pallets. By any shredding, industrial plastic shredding, scrap shredder, these materials, they become easier to transport and dispose of, reducing the amount of space they take up in landfills.

Hazardous Waste: Twin shaft shredders machine in India can also be used to shred and process hazardous waste materials, such as medical waste and electronic waste, Plastic waste, scrap. This helps to ensure that these materials are properly disposed of and do not pose a risk to the environment or public health.

Plastics: MSW Twin Shaft Shredder or Twin Shaft Shredders Machines are ideal for processing plastics, including hard and soft plastics, which can then be recycled and used to produce new products.

Wood: Twin shaft shredders can also be used to shred and reduce the size of wood, including branches, pallets, and furniture, which can then be used as biomass fuel or processed further into wood chips or sawdust.

Rubber: Twin shaft shredders are also commonly used to process rubber products, such as tires, conveyor belts, and rubber mats. The shredded rubber can then be recycled or used for other purposes, such as playground surfaces or athletic fields.

Overall, twin shaft shredders have many applications and can be used in a variety of industries to reduce waste, increase efficiency, and save money.

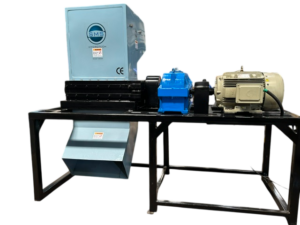

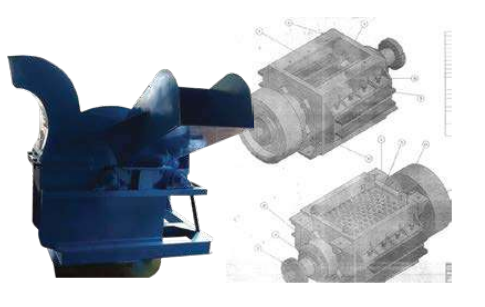

Features

The blade is made of the high alloy 42CrMo, which has high strength and toughness and is difficult to break.

The blade is made of the high alloy 42CrMo, which has high strength and toughness and is difficult to break.- The blades of the K-rotor and D-rotor are made of D2, and the main body is made of 42CrMo.

- The main electrical components are manufactured by well-known companies such as Siemens and Schneider.

- Automatic protection is designed to avoid machine overload and jamming.

- High torque, Low speed, Low noise, and High efficiency.

- CE Standard-Safety Devices are CE Certified.

Twin Shaft Shredder Key Benefits

- Twin Shaft with Twin Motor & Gearbox no Power Transmission loss

- Die Steel/EN9/SS Blades as per Application.

- Sturdy Design

- Plug & Play Installation

- Auto Reverse & Forward Safety Feature

- Auto Feeding and Output Conveyor available as additional accessory.

- Horticulture/Agriculture

- Waste Shredder

- Plastic Waste Shredder

- Food Waste Shredder

- Tire Waste Shredder

- Scrap Shredder

Metal materials: Aluminum, Ferrous, Non-ferrous,Steel scrap,Metal drum

Electronics: Waste household appliances,WEEE, Hard disk, Electronic equipment

Plastic: Plastic drums, Plastic lumps, Waste household plastic, Films

RDF(Refuse Derived Fuel): MSW, Solid waste

> Shredder Chamber Includes Sharp Cutting Edge Blades.

> Power System; Coupling, Gear Box & Motors

> Powerful Electrical Control Panel and Discharge System

We delivers high quality high strength quality with high durable material used for better quality and provide long lifespan products.

HORTICULTURE WASTE SHREDDER

Capacity Available:

50Kg/hr, 100Kg/hr, 250Kg/hr,

500Kg/hr and 1000Kg/hr

Shredder Output:

Powdered / Chipped / Saw Dust

PLASTIC WASTE SHREDDER

Capacity Available:

50Kg/hr, 100Kg/hr, 250Kg/hr,

500Kg/hr and 1000Kg/hr

Shredder Output:

Shredded Plastic Waste

FOOD WASTE SHREDDER

Capacity Available:

50Kg/hr, 100Kg/hr, 250Kg/hr,

500Kg/hr and 1000Kg/hr

Shredder Output:

Shredder Food Waste / Food Slury

TYRE WASTE SHREDDER

Capacity Available:

50Kg/hr, 100Kg/hr, 250Kg/hr,

500Kg/hr and 1000Kg/hr

Shredder Output:

Mixed Shredded Tire Rubber